This article is simply going to serve as a quick list of a few “dos” and “don’ts” – for the full story, watch the video above!

but a thinner cable will generally last longer than a thicker one at the same radius

Spiral warp: Bundles wires and has them supporting each other

Mesh sleeving: Does little to support wires, but keeps them tidy

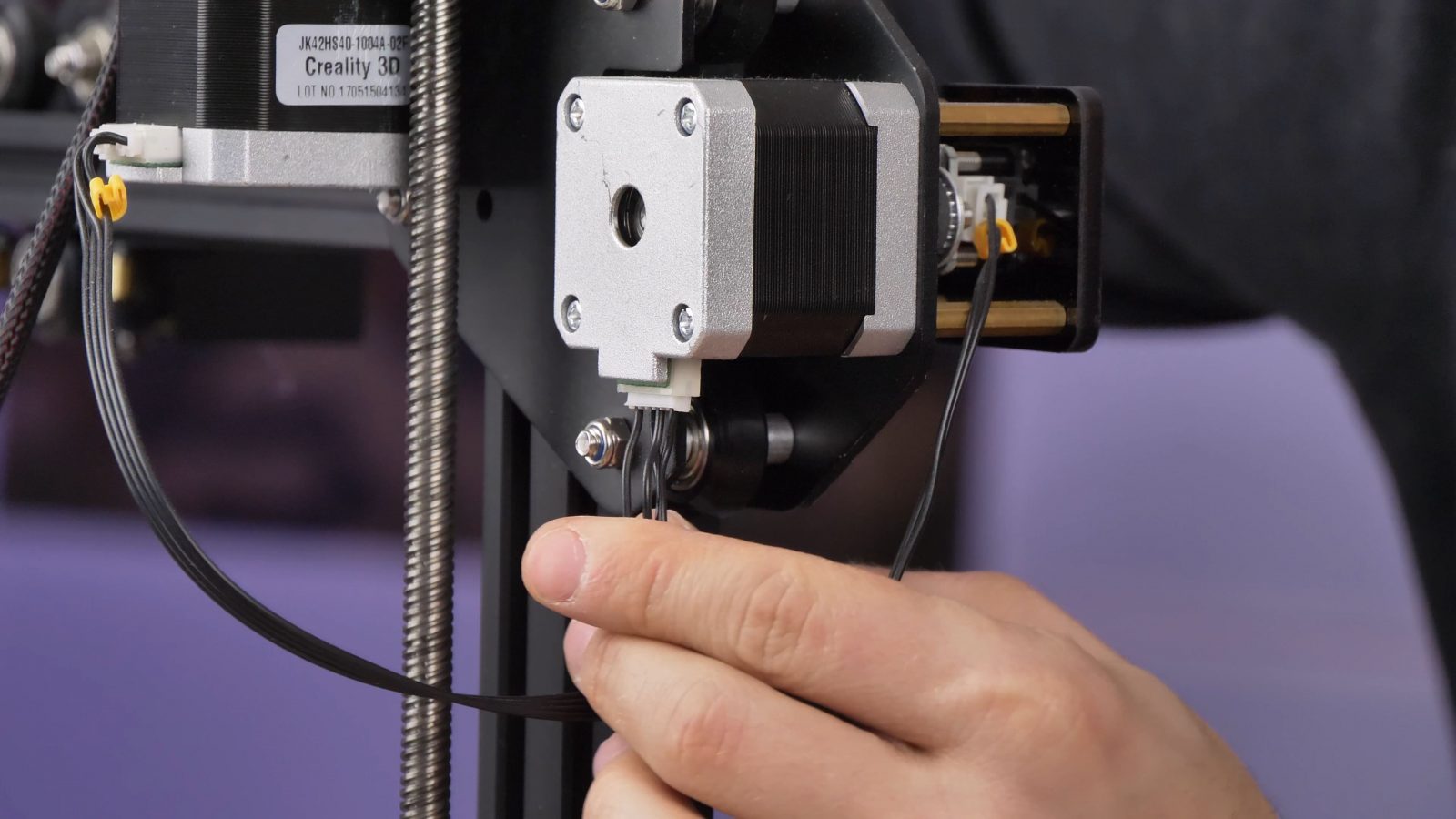

Good design: Strain is taken off the connector with the cable support

Bad design: No strain relief, solder joint and wire right next to it sees maximum stress

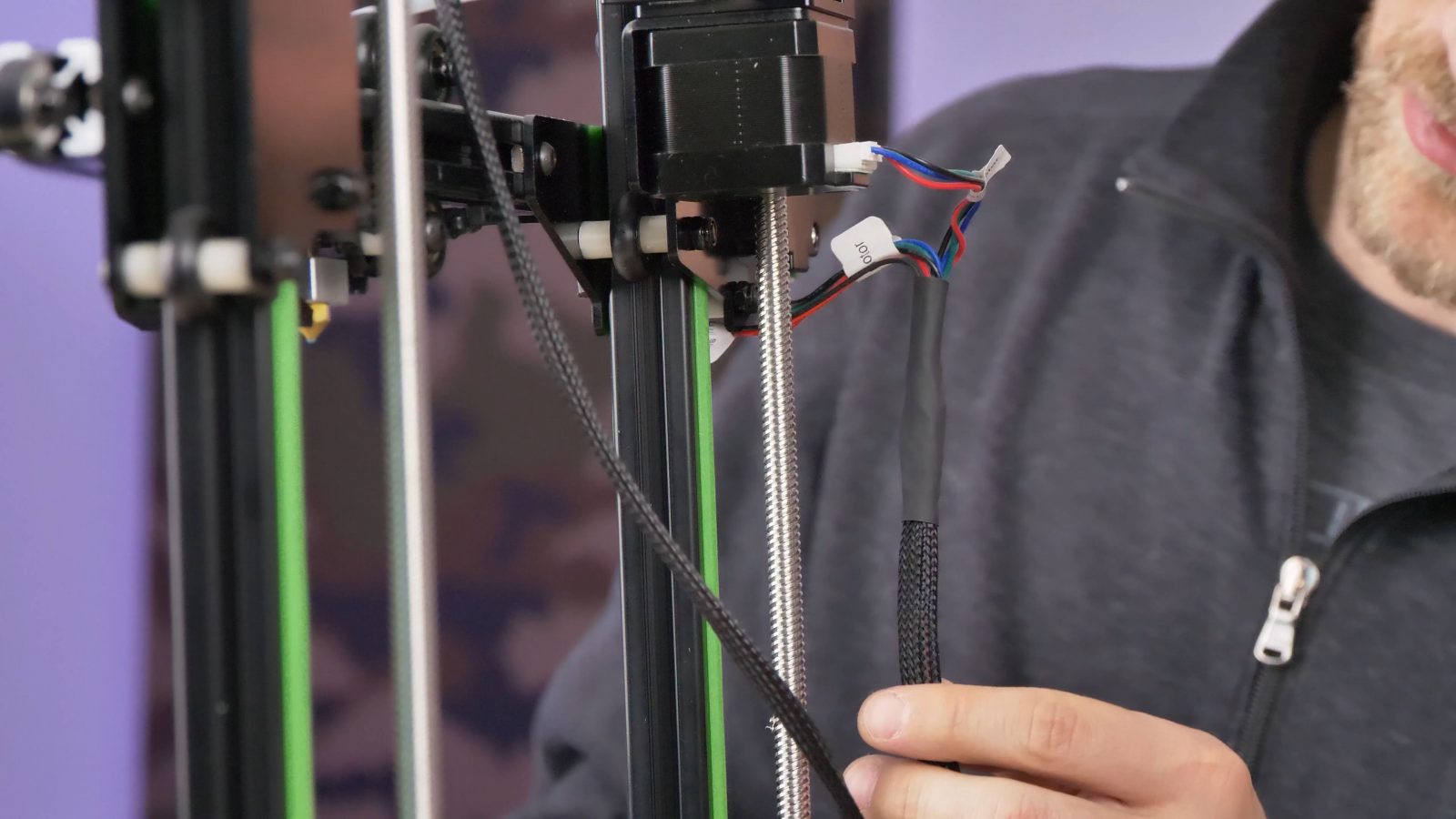

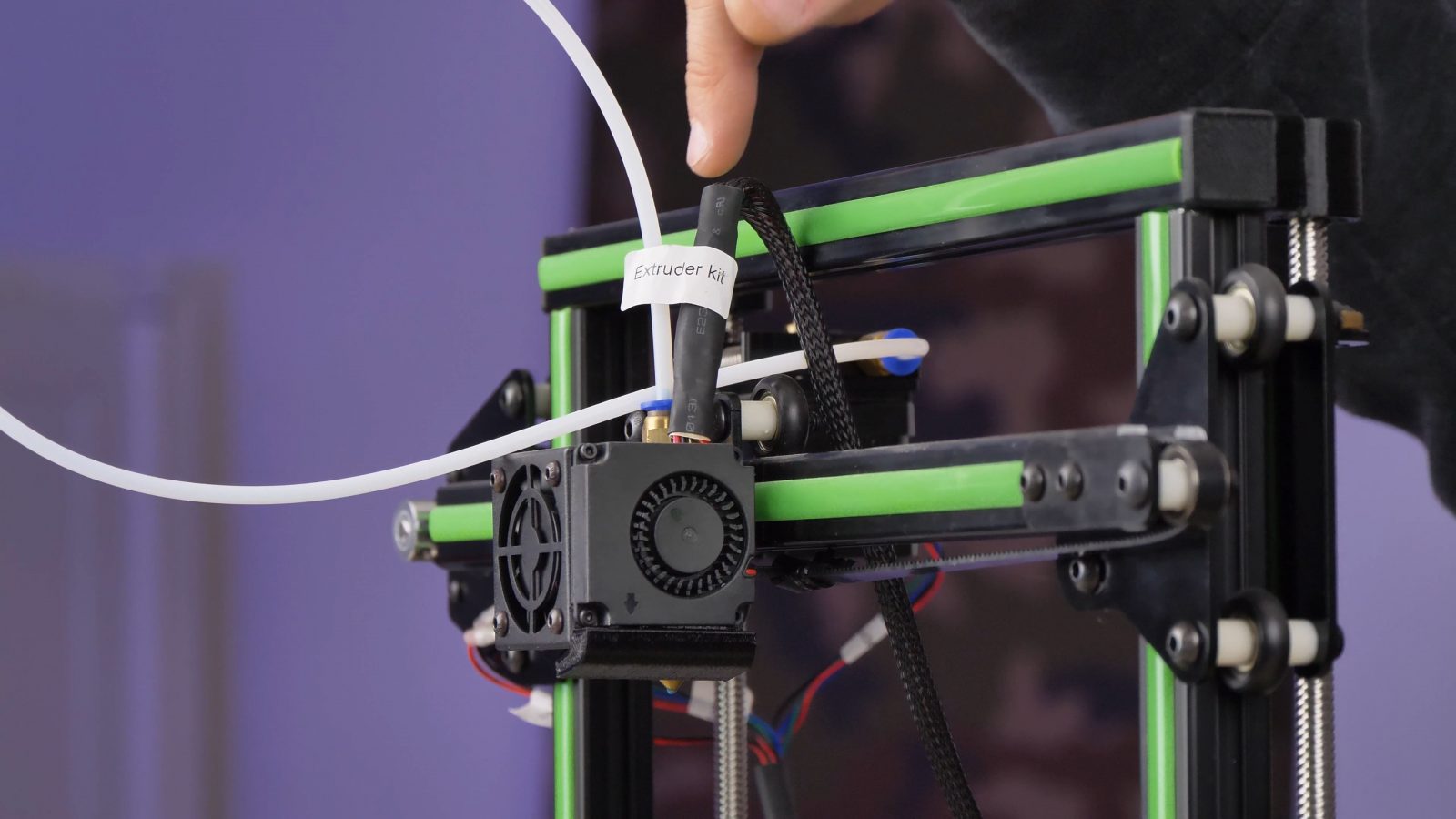

Good design: Extruder wiring reinforces with bowden tube

Bad design: No strain relief at connector, but acceptable for the Z-axis

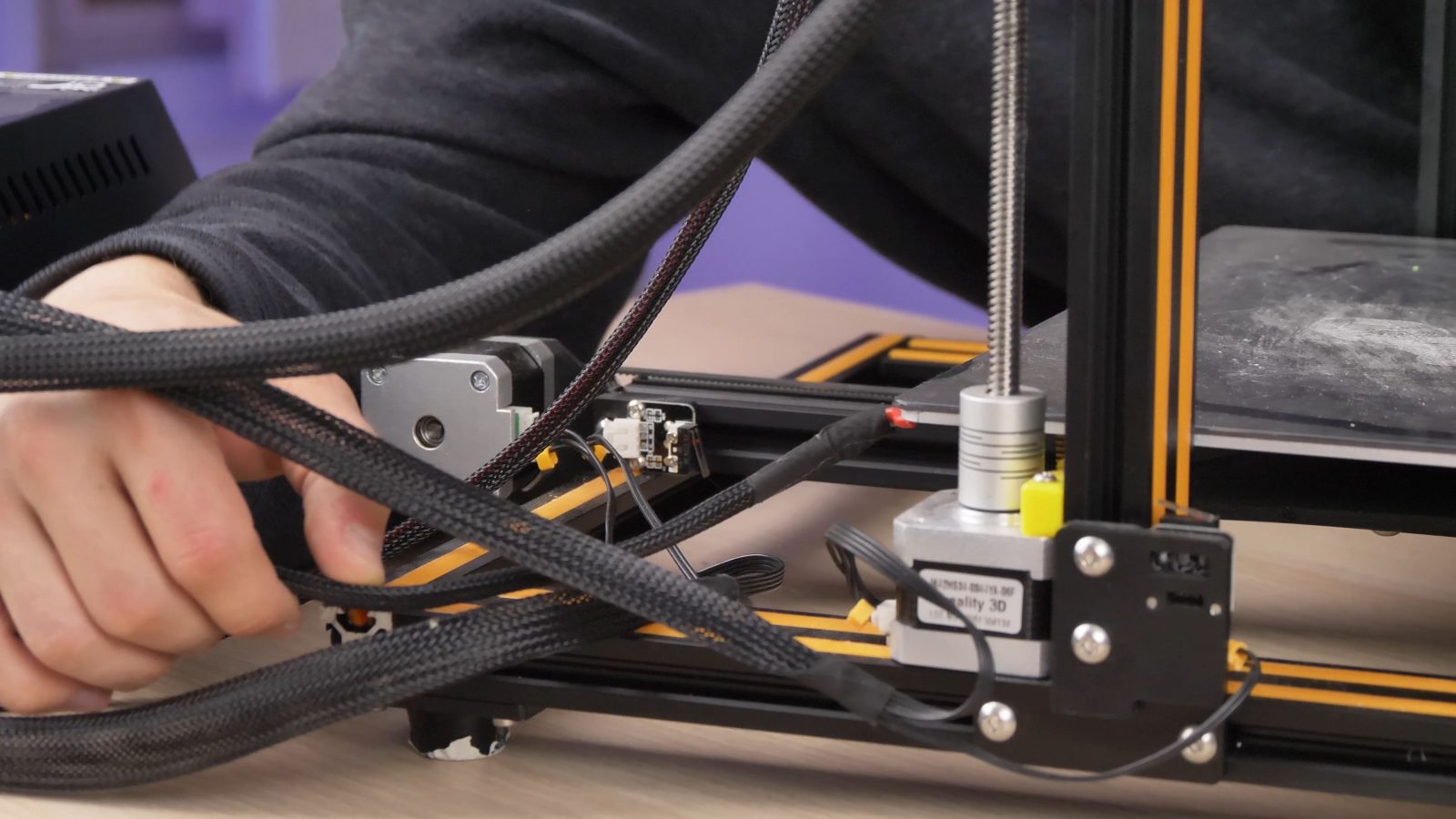

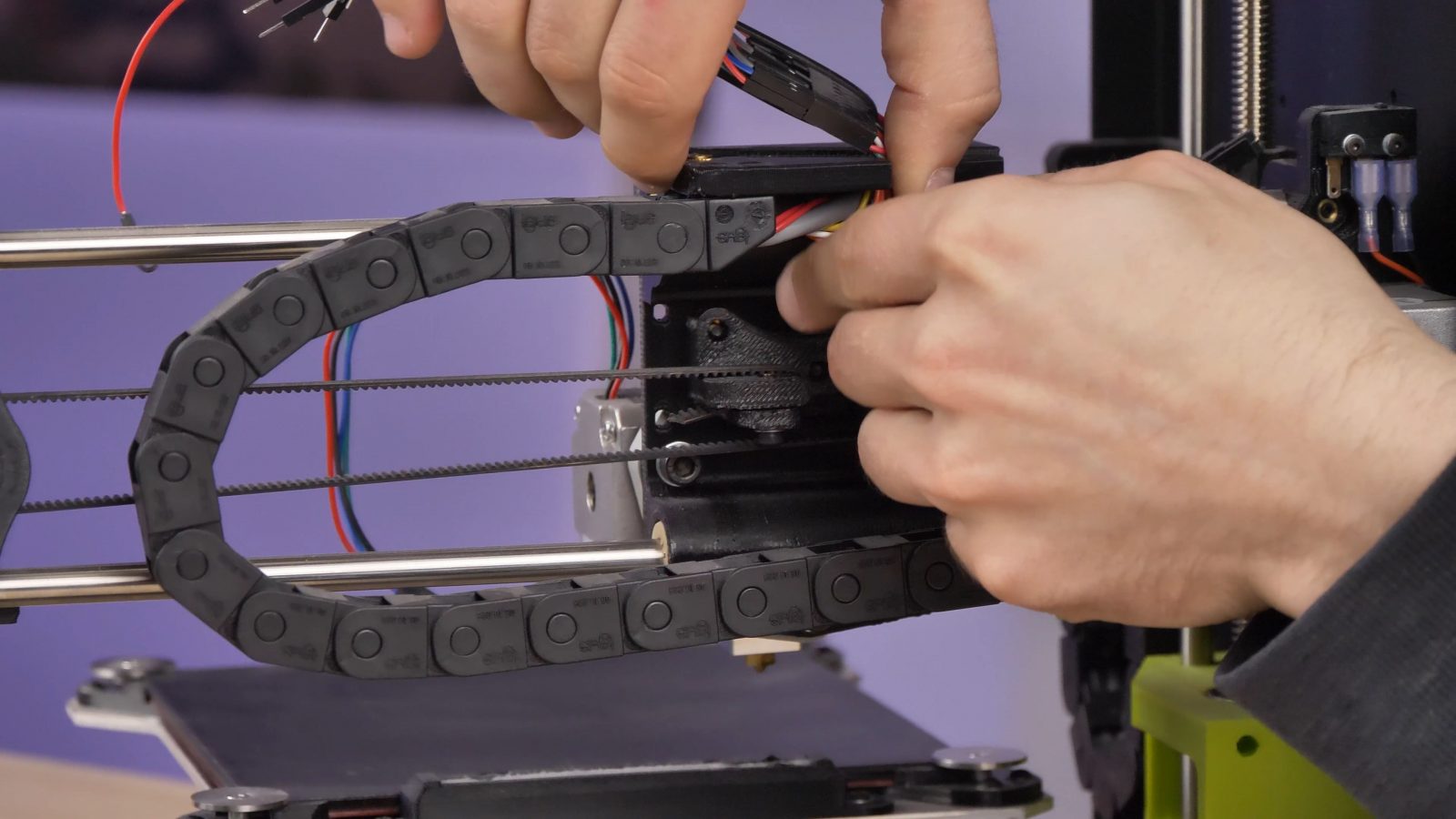

Bad design: Loose wiring and missing strain relief

Bad design: Crimped plug sees continuous movement

Regular cable can work in relatively tight radii if it doesn’t see much movement

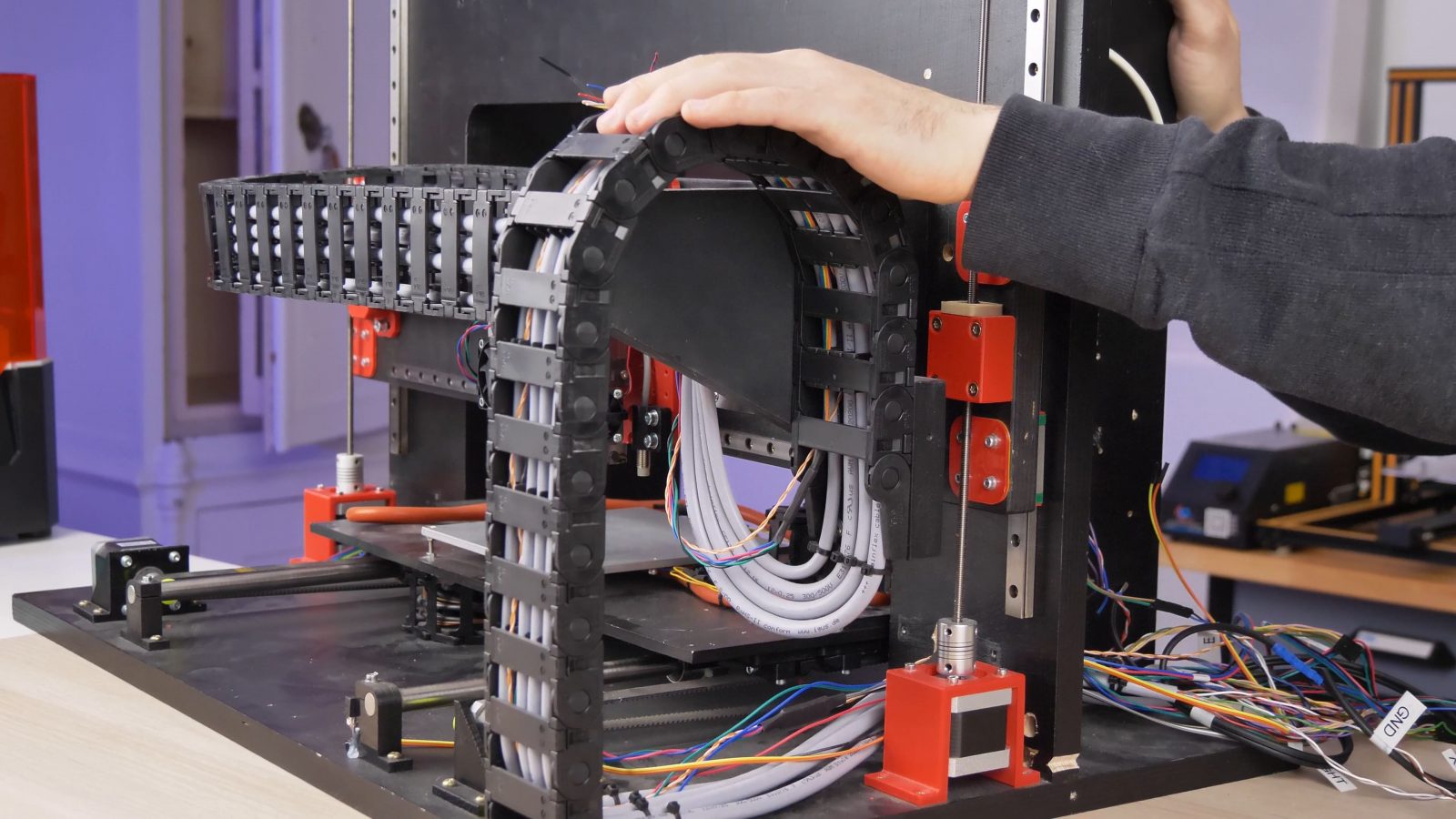

Good design: Thin cables and a relatively large radius

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams