Ok, let’s talk about some basics today. A little while back I did a video on how you can combine 12, 24, 5V components in the same setup and on that video, a bunch of you asked in the comments why ATX computer power supplies aren’t really used anymore in 3D printer builds. So let’s try and find out what had these falling out of favor and check out some of the things you can do with an ATX supply that would be really tricky with these simpler ones.

ATX supplies vs. industrial type power supplies

Form factors

There are a few pros and cons to each one, and it’s not like one is always clearly better than the other. So let’s start with the obvious differences, first, ATX supplies have a standardized shape that is kind of bulky in every direction, while the industrial supplies are slimmer, but also longer.

That makes it a bit easier to tuck them for example under the print bed, but the ATX form factor can work really well on some printer builds, too. Just typically, this type of form factor can be used more flexibly. There are also other PC power supply form factors that are made to plug into the same type of motherboard and components, for example the SFX size or Mini-ITX, which is just a shrunken down version of ATX. Those are typically a bit more expensive, though.

Set of wires

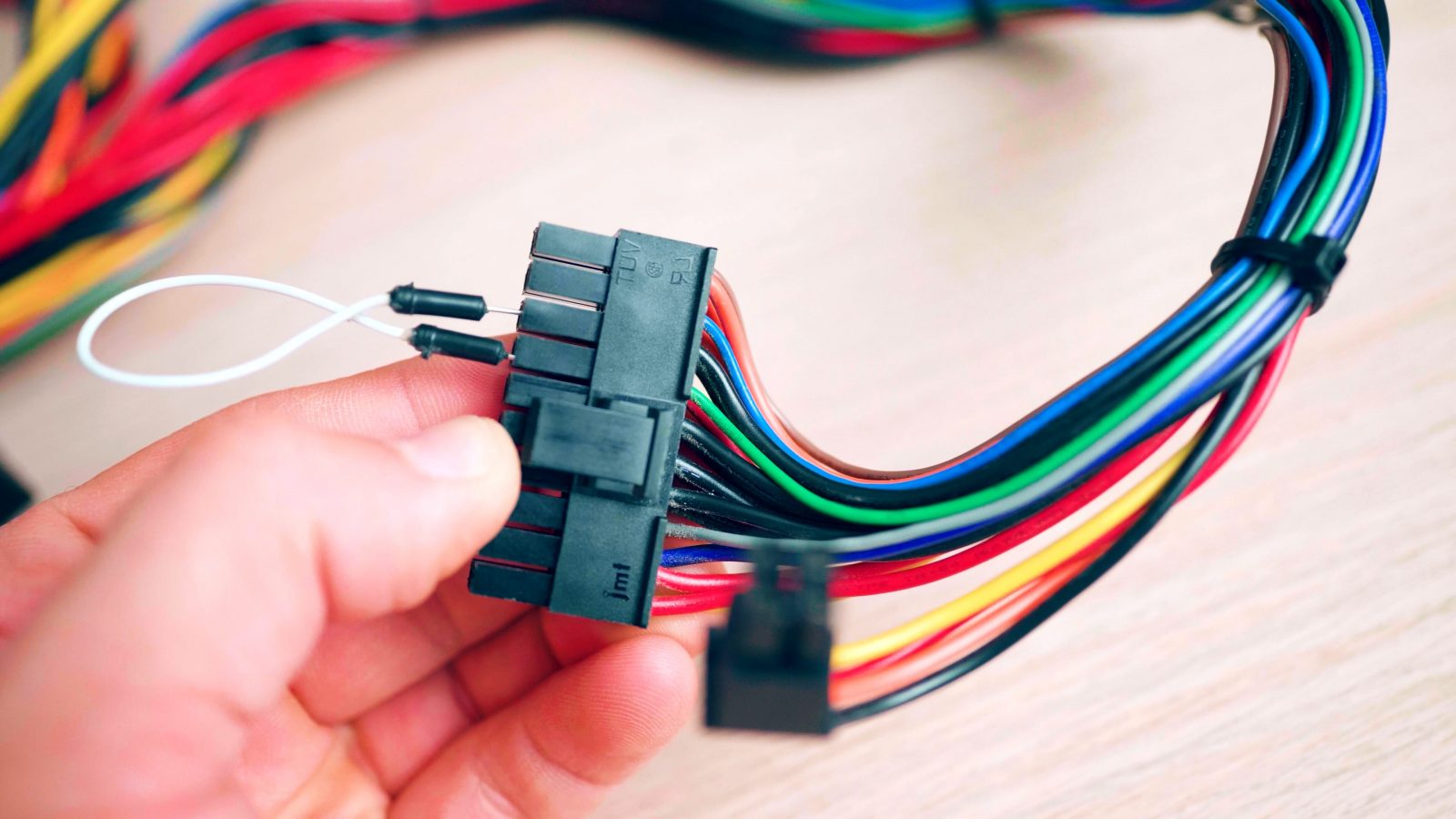

Now, the other difference you can see right away is that the ATX supply has a set of wires it comes with.

Some of the better units are modular, so you can just plug in the wiring looms you actually need, but typically, all of these are all permanently attached to the supply. On more powerful supplies, the wiring itself can take up as much space as the unit itself because it’s got enough plugs for 20 hard drives, four graphics cards, two mainboard and 12 floppy drives. I always find it kind of heartbreaking to cut off the connectors from a perfectly good power supply, but the plugs on here really are only used in computer parts. Also, just one wire by itself can not handle the entire output power, so if you need more than 100 or 200W, you’ll have to splice together wires from different plugs, and that can get really messy.

More on that in a second, as there’s more to it, but one upside of having standard connectors is on the input side, where you’ve got the standard IEC receptacle, so at least on the mains, high voltage side, you have a really easy, clean and safe way to plug it in.

The industrial supplies just come with a bunch of screw clamps that you can tighten onto crimped connectors or bare wire, but not onto tinned wire, but that’s both for the AC mains input as well as the DC output, so you’ll have to hook up mains to it yourself, too. On the upside, each of these clamps on the output can basically carry the entire output current with a single wire as long as the wire itself can handle it.

Ok, to expand on why you need to splice together wires on the ATX supply. The industrial supplies and also some simpler ATX units have just what’s called a single “rail”, basically one single output for 12V. But more more commonly on ATX supplies, there are two, three or four 12V rails, which are basically several independent supplies. One rail might supply the plug for the mainboard and power the CPU, another rail might be for one set of PCIe connectors for the graphics card and then another rail for the other set of PCIe connectors.

Now, it’s not entirely perfect just tying these separate supplies, these separate rails together, but it’s going to work to supply more current if you’re for example powering a large 12V heated bed. But to make use of the full output power, you will need to know which connectors are connected to which rails and grab power from each one, or just tie them all together.

Group regulation

And another thing that comes along with these supplies being built for computers is that they don’t just generate 12V, they also generate 5V, 3.3V, -5V and -12V, those last two ones are often used for audio.

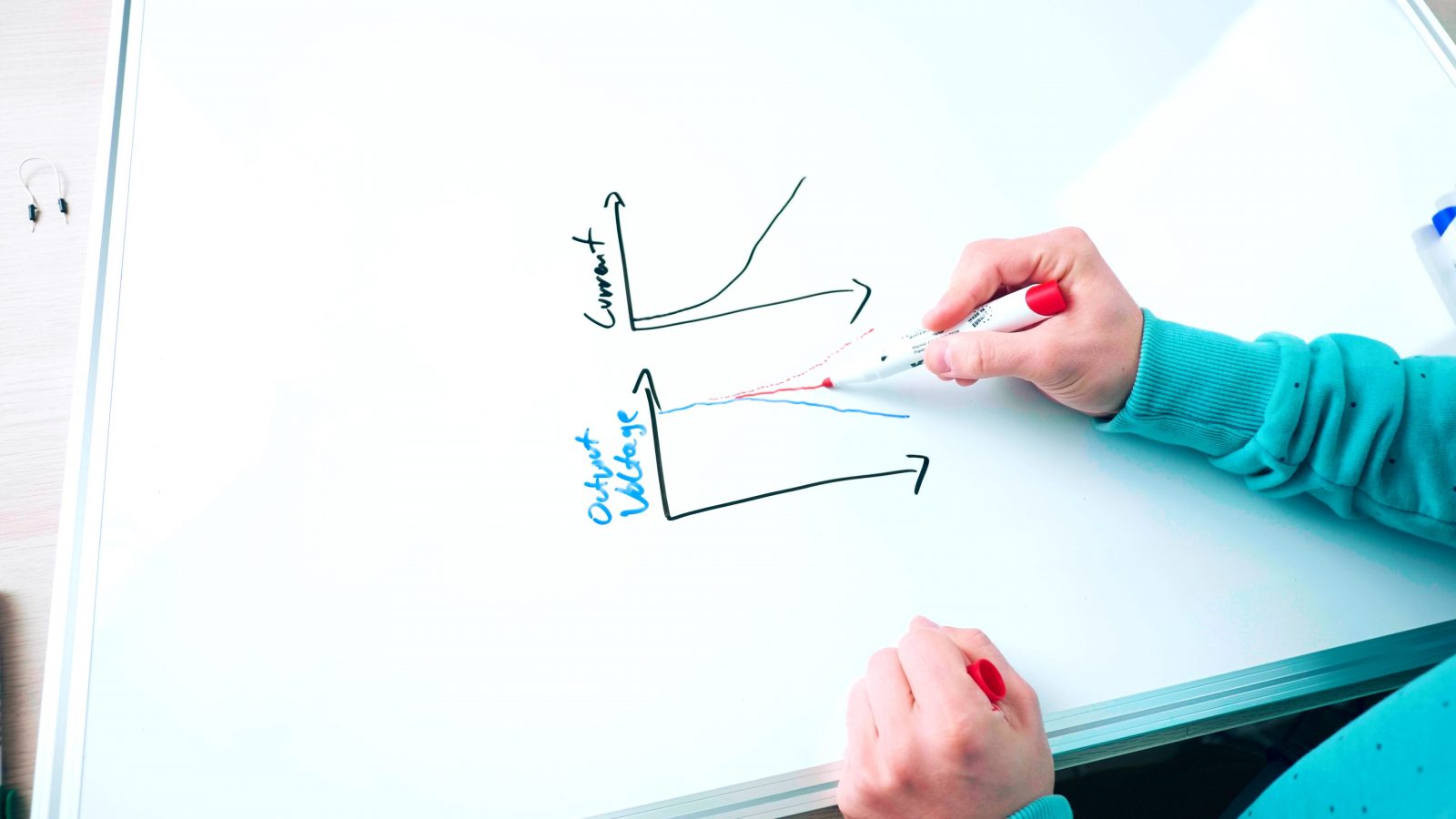

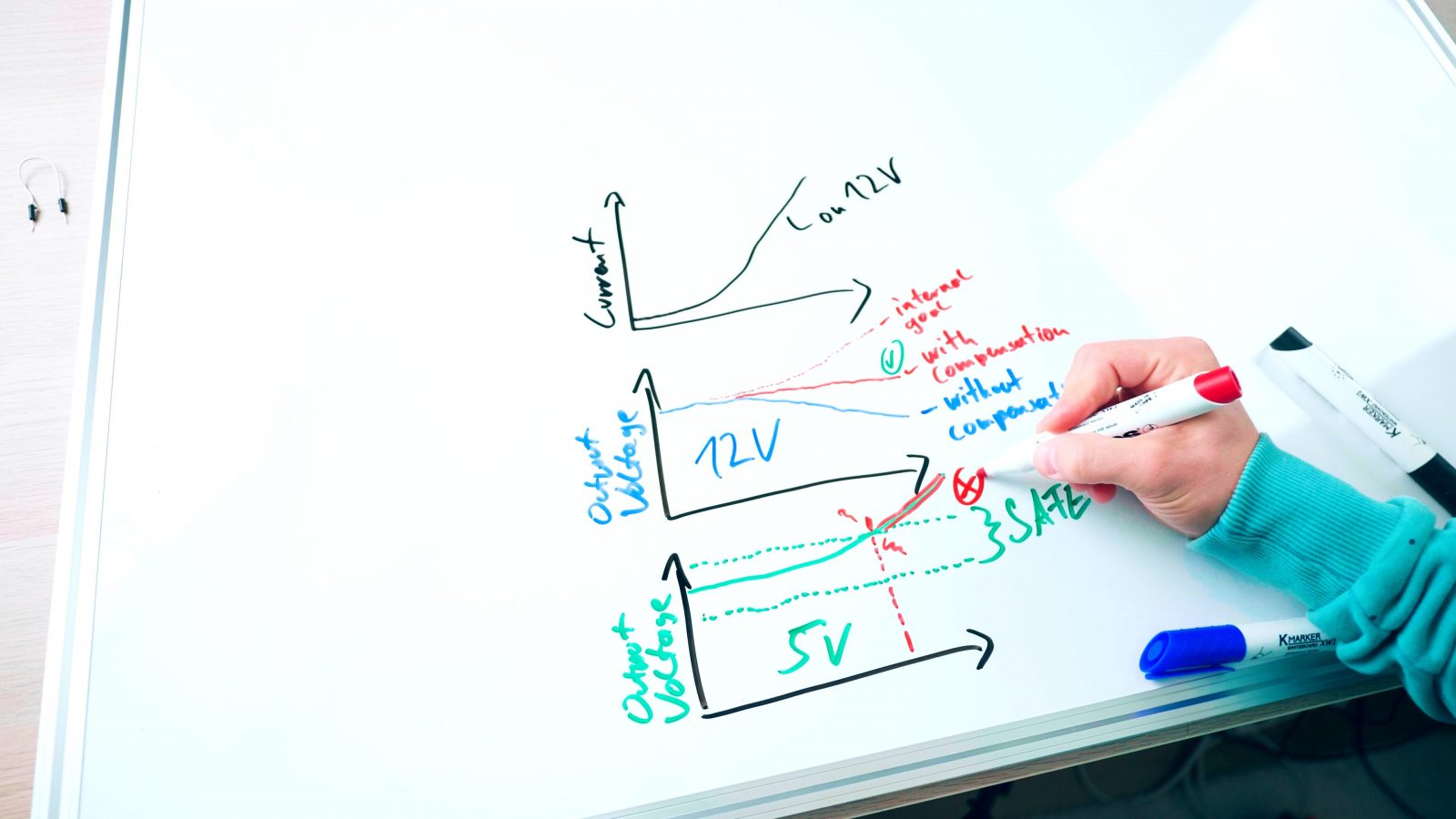

Now, on cheapers supplies, you’ll often find what’s called “group regulation”. In very simplified terms, these power supplies will regulate 12V, 5V and 3.3V together so that the voltages are just fixed ratios to one another, that simply saves cost because you only need one transformer that has multiple secondary windings. As we start drawing current from 12V, the voltage on 12V will slightly drop because we start having resistive losses inside the supply, so it will start trying to compensate for those losses by slightly increasing the voltage it’s trying to achieve, so that the actual output voltage will more or less stay constant, no matter if you draw 1A or 20A.

But with that group regulation, not only will the power supply compensate for that voltage drop on 12V, at the same time it will also increase the output voltage on 5V and 3.3V even though we aren’t drawing any current here. The safety mechanisms in the supply are still monitoring those two voltages, though, and if they go above the safe limit, it’s going to shut itself off.

And that’s not uncommon to happen if you have a cheap supply and are drawing a good amount of load just from 12V, so one way to fix that, and that’s been done a lot, actually, is to just add a load to 5V and maybe 3.3V, all that needs to be is a resistor that wastes a few watts of power. I mean, I don’t think that’s very elegant, and I’ve not had to do it on any of my supplies yet, but then again, I don’t buy the very cheapest ATX supplies usually because I will probably use them in a PC at some point.

Efficiency

Next up, efficiency. If you’ve got cheap, subsidized, coal power, then you probably don’t care about a few extra watts that much, but when you’re paying 25 or 30ct per kWh, you probably do. Cheap industrial supplies will often claim “85-90% efficient”, which is hard to believe to say the least, typically they only manage about 70%. So if you have a printer that needs 100W to run, it will actually draw an extra 43W from the wall just for losses inside the power supply.

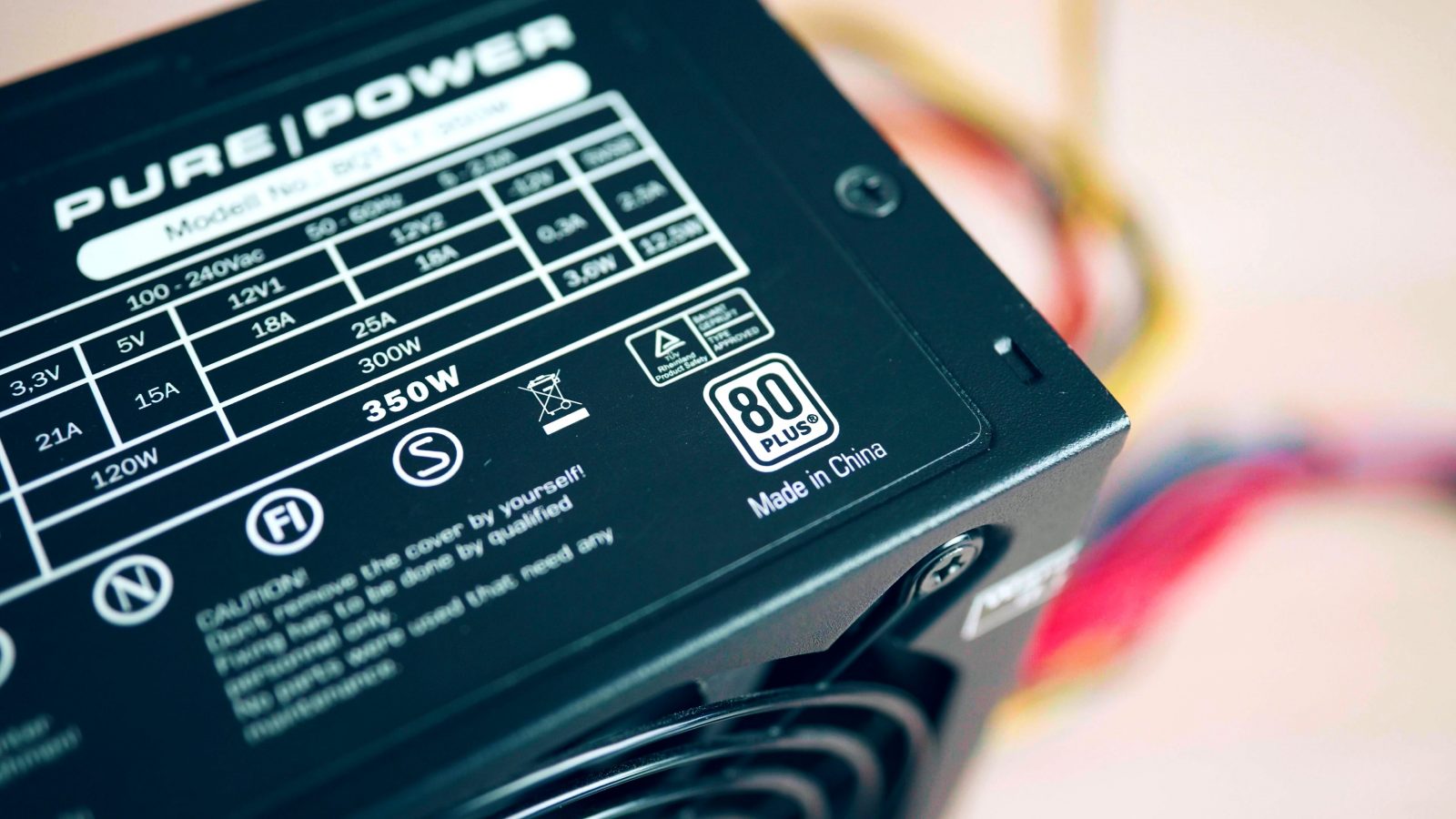

Brand-name industrial supplies are a lot better here, like the ones from Delta, Meanwell etc., but for ATX supplies, you have the “80+” certifications, which come in Standard, Bronze, Silver, Gold, Platinum and Titanium.

The higher you go up in level, the more efficient the supply will be across its entire load range, between 20% and 100% load. If a cheap supply only tells you one efficiency figure, that’s only for peak efficiency at one specific output load. Also, that achieve that better efficiency, 80+ supplies usually also use better components.

Switching on and off

Another upside of ATX supplies is the fact that you can switch them off. Not just with that switch on the back, which of course it super convenient, too, but by signaling through that green wire, you’ll no doubt have shoved a wire into the ATX connector before to turn it on or you’ll have seen these jumper plugs.

There are two incredibly cool things about this: First, we can control that signal with any 3D printer mainboard. Marlin has support for switching on and off an ATX supply, it’s right there in the config, so with one gcode command, you can enable all the high-power parts on your printer that are connected to the 12V line from an ATX supply, and with another, you can turn them off again, and you can even use that as an emergency stop for example through OctoPrint. You can also use those gcodes in the start and end gcode, so that before and after a print, the printer turns itself on and off automatically, that saves some standby power and reduces the risk of anything dramatic going wrong when the printer is just sitting idle.

But the cool thing with that is that an ATX supply always provides 5V power for your electronics, even when you’ve switched it off electronically through the green wire.

The 5V_SB line provides enough current for at least a printer control board, and in many cases also enough for a Raspberry Pi so that you don’t need a separate power supply for that.

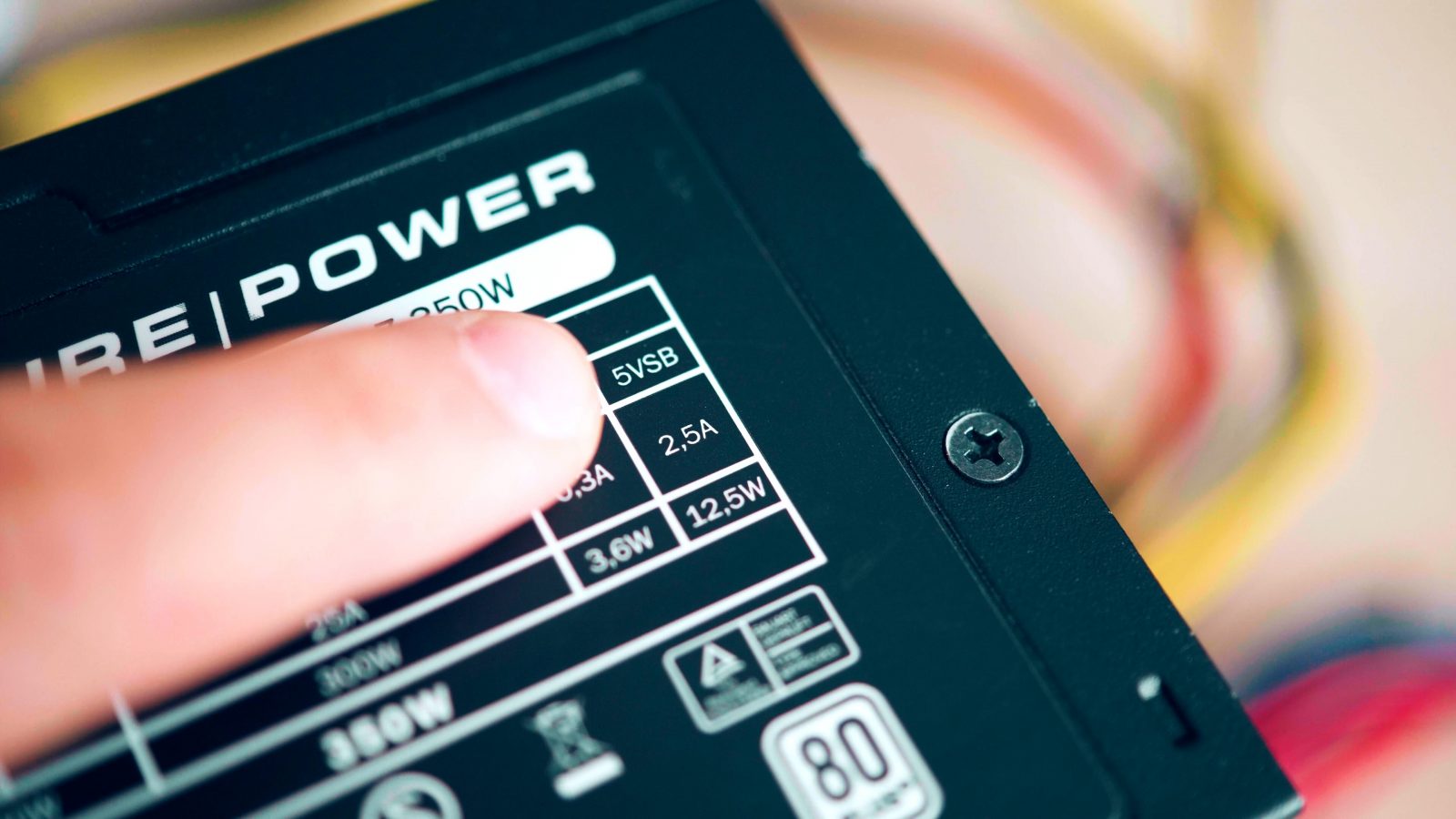

5V_SB is intended for keeping some functions enabled in a computer when it’s off, like wake on LAN, and more recently also to allow charging through the USB ports. Check your power supply for the exact current rating.

Voltage

So ATX supplies actually sound pretty cool so far, right? Well, there are two more things that are fairly strong arguments against using them. The first one is voltages. Now, printers have been moving to 24V because it’s easier to handle powerful heated beds with it as you’re reducing the current that’s needed to get the same output power, but it also gives stepper drivers more headroom to breath and actually improves the performance for higher movement speeds and fast accelerations in many cases. But of course, ATX supplies are only available with their main output voltage at 12V, while you can get these industrial ones in 5V, 12V, 24V, 36V, or 48V. Now, you or a printer manufacturers can work around that by for example carefully selecting the stepper motor and driver to work well at 12V, that’s totally doable, and move to a mains-powered heated bed. But then, of course once you do that, you don’t even need a power supply as capable as an ATX unit anymore, you can get away with one of these small brick-type supplies.

Price

And the other factor, of course, is price. These industrial units have become incredibly cheap, spurred by an LED strip craze a few years ago and 3D printers coming up around the same time, so I just did a quick search for how much these are, shipped from Germany, taxes included;

A 12V 20A supply is 14€, a 30A unit is 16€, and a 24V, 10A unit, the same rating as in the MK3 is also 16€.

That is just incredibly hard to beat. Now of course, that’s the bargain bin quality units, so if you go for one of those, you should always buy one that’s rated for at least 30% more than you think you’ll need, and also, they will age over the years and lose some of their ampacity as the capacitors dry out, but the same exact thing also applies to super cheap ATX supplies. Now, with those you have to factor in that connectors are actually surprisingly expensive, even if you buy them in bulk, which is why modular supplies are so much more expensive than regular ones.

So you can get a “500W” unit, rated for 26A, so more like 300W, of which you should maybe use like 220W, for 16€, plus shipping this time, you can get a “600W” unit with two 20A rails, for around 22€, and then as we get into actually decent, brand-name, 80+ certified units, they start around 32€, 35€ for between 24 or 30A of output on 12V. Plus shipping.

Now, honestly, that’s still not super expensive, but you can also get an industrial Meanwell power supply at 12V and 20A, or 24V and 10A for about 40 bucks. Honestly, if you’re building a printer, you’re ok with a 12V system, want a decent supply and maybe are thinking about using that 5V standby line, which I think is a really neat feature, then an ATX supply is still a really good choice.

But when it comes to manufacturers, not only are they probably getting even better deals on industrial supplies in bulk, but for them, a smaller packaging size is also worth a lot as it saves on logistics, and dealing with ATX connectors also adds cost and complexity because they’ll need to have some solution to plug all relevant cables in, which means making a custom PCB or another wire harness, spending money on connectors again and also spending more time during assembly. For them, I think it just makes a lot more sense to use the industrial supplies.

So if you’ve built a printer or customized one, let me know what you’ve used! Is the option for 24V the deciding factor? Maybe you’re also using an ATX supply with a boost converter just for the stepper drivers? Would totally make sense!

Get 24V 10A supplies

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams